FEATURED PRODUCTS

-

DOUBLE BEVEL 100

Vendor:Annihilator Broadheads4.7 / 5.0

(110) 110 total reviews

Regular price $69.99 USDRegular price -

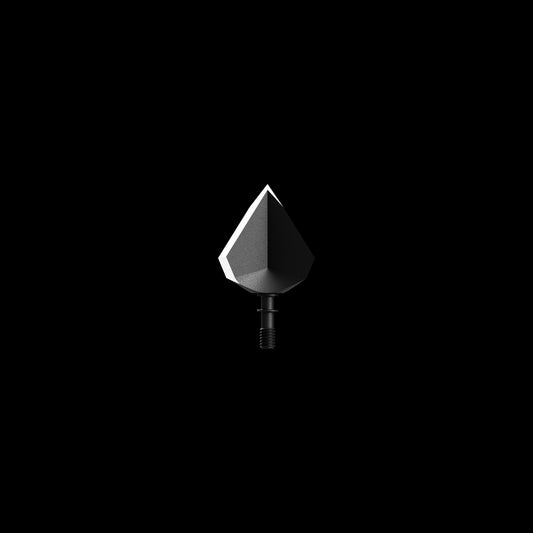

KATANA 100

Vendor:Annihilator Broadheads4.8 / 5.0

(41) 41 total reviews

Regular price $89.99 USDRegular price -

SINGLE BEVEL 100

Vendor:Annihilator Broadheads4.8 / 5.0

(26) 26 total reviews

Regular price $74.99 USDRegular price -

KATANA 125

Vendor:Annihilator Broadheads4.7 / 5.0

(43) 43 total reviews

Regular price $89.99 USDRegular price -

SINGLE BEVEL XL 100

Vendor:Annihilator Broadheads4.8 / 5.0

(5) 5 total reviews

Regular price $79.99 USDRegular price -

DOUBLE BEVEL XL 100

Vendor:Annihilator Broadheads4.7 / 5.0

(62) 62 total reviews

Regular price $74.99 USDRegular price -

SINGLE BEVEL XL 125

Vendor:Annihilator Broadheads5.0 / 5.0

(6) 6 total reviews

Regular price $79.99 USDRegular price -

DOUBLE BEVEL XL 125

Vendor:Annihilator Broadheads4.6 / 5.0

(37) 37 total reviews

Regular price $74.99 USDRegular price

most shots aren't perfect

Why Annihilator?

Every broadhead can take down an animal with a well-placed shot—you already know that. But what actually causes an animal to expire? Sharp blades disrupting vital organs, inducing hemorrhage, and reducing function until collapse.

maximum impact

Holes That Stay Open

Unlike traditional broadheads that slice narrow slits, Annihilator Broadheads are engineered to remove mass—punching large, open holes that stay open.

Built to last &

Easy to Sharpen

Annihilator Broadheads are made from a premium alloy steel engineered for extreme strength and resilience under dynamic stress.

Annihilator Broadheads

KATANA 100

Share